PRODUCT FEATURES

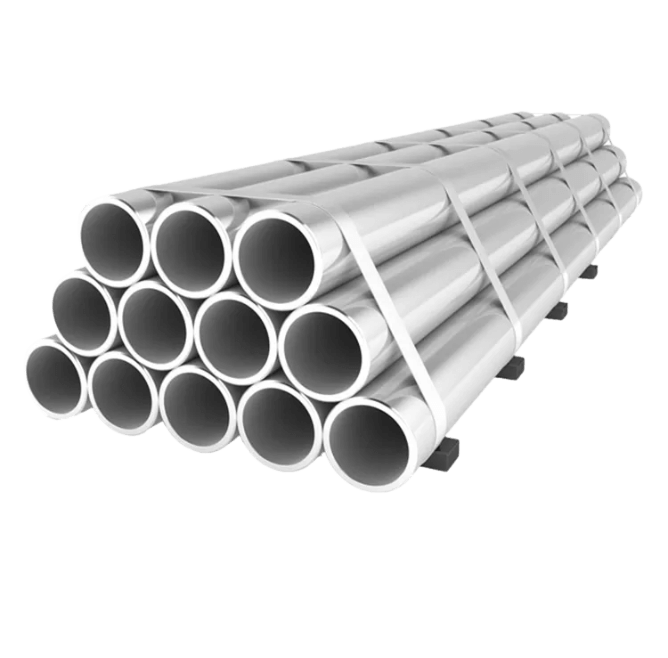

Aluminum Tube Manufacturer to Rocket Your Business

PRODUCTS

Proud to Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today.

ABOUT US

Who is Upaluminum.com

Upaluminum.com have seen that today there are also many aluminum coils companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and upaluminum.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

Aluminum Tube Manufacturer: The Ultimate Guide for Wholesalers

Choosing the right aluminum tube manufacturer is essential for your business. With so many options available, it can be difficult to know which one is the best fit for your needs.

This guide provides a comprehensive overview of what an aluminum tube is, its features and types, as well as the different industrial applications for this product. This will also outline the steps and tips on how to find a reputable manufacturer that will suit your business requirements.

So, whether you’re looking for a small-scale or large-scale aluminum tube manufacturer, read on to find out everything you need to know about this essential piece of metal.

Table of contents

1. Aluminum Tube: The Basics

An aluminum tube is a hollow cylinder that is used in a variety of applications. It is often made from aluminum alloy, which is lightweight and strong. Aluminum tubes can be used to transport fluids or gases, as well as to store and protect fragile items. They are widely used in the construction, automotive, and aerospace industries.

Aluminum tubes are often manufactured using an extrusion process, which involves pushing molten aluminum through a die to create the desired shape. The finished product can then be cut to the desired length and sealed at the ends.

2. Key Features

Aluminum tubes are one of the most versatile products used in a variety of industries. Here are some key features that make them an ideal choice for many applications:

High Strength-To-Weight Ratio

Aluminum is about one-third the weight of mild steel, yet it is strong enough to be used in construction and other applications where a strong material is required. This makes aluminum an ideal choice when weight is a factor, such as in aircraft construction.

Resistance to Corrosion

Aluminum naturally forms a protective oxide layer on its surface that helps prevent corrosion. This makes it an excellent choice for applications where rust and other forms of corrosion could be a problem, such as in marine environments.

Good Conductivity

Aluminum is a good conductor of electricity and heat, making it ideal for electrical and thermal applications. It is also often used in cookware because it heats up evenly and quickly.

Non-Toxic

Aluminum is non-toxic and will not leach into food or water, making it a safe choice for food and beverage containers. Also, it does not emit fumes when heated, making it a safer choice for cooking than some other metals.

Recyclable

Aluminum can be recycled indefinitely, making it a sustainable choice for products that need to be replaced frequently, such as cans and foil.

3. 5 Industry Application

Aluminum tubes are one of the most versatile packaging materials available on the market today. Their lightweight, durability, and ability to withstand extreme temperatures make them ideal for a variety of applications across many industries. Here are 5 industry applications for aluminum tubes:

Chemical

Aluminum tubes are widely used in the chemical industry due to their superior corrosion resistance. They are used to transport and store corrosive chemicals such as acids, bases, and salts. Aluminum tubes are also used in the manufacture of chemicals such as aluminum oxide and aluminum chloride.

Petroleum

Aluminum tubes are used to transport crude oil and natural gas from wells to refineries. Aluminum tubes are also used in the construction of offshore oil rigs. It is estimated that over 70% of all offshore oil rigs are made of aluminum.

Automotive

Aluminum tubes are used in the construction of vehicles such as cars, trucks, and buses. Aluminum tubes are also used in the manufacture of automotive parts such as engine blocks and cylinder heads. Also, aluminum tubes are used in the construction of fuel tanks and exhaust systems.

Aerospace

Aluminum tubes are used extensively in the aerospace industry. They are used in the construction of aircraft, missiles, and satellites. Aluminum tubes are also used in the manufacture of aerospace parts such as landing gear and fuselage sections.

Construction

Aluminum tubing is used extensively in a wide range of construction applications, including scaffolding, support structures, and curtain walling. It is also often used to create energy-efficient windows and doors.

4. Finishing Types

Metal tubing needs a finish and coating on both the inside and outside, but it must be a certain type of finish, like:

| Galvanized | Bright Finish | Plated | Painted |

|---|---|---|---|

| The process of galvanization involves coating the aluminum with a layer of zinc, which protects the metal from corrosion and oxidation. | Wide range of applications, from packaging cosmetics to medical supplies. | More lightweight, making them easier to transport and install. | Has durable and low maintenance requirements |

| More durable than uncoated aluminum, and they are also less likely to show signs of wear over time. | Durable and corrosion resistant | More resistant to corrosion, making them ideal for use in high-humidity environments. | Popular choice from architectural cladding to furniture, for both indoor and outdoor use. |

| Often less expensive than other types of metal tubing, making them an attractive option for budget-conscious consumers. | Durable and corrosion resistant | Can be quickly and easily cut to size, making them ideal for use in custom applications | Long-lasting finish |

| The smooth surface of bright finish aluminum tubes makes them easy to clean and sterilize, ensuring that your products remain safe and contamination-free. | Offer a high level of resistance to corrosion and UV damage. | ||

| When it comes to packaging, bright finish aluminum tubes offer a sleek and modern look that can boost the appeal of your products. | Excellent choice for applications where long-term performance is essential. |

5. The Difference Between Aluminum Tube and Pipe

The main difference between aluminum tubes and pipes is that tubes have a round, hollow shape while pipes are typically solid and have a more rectangular shape. While both are made from aluminum, their different shapes and applications require different manufacturing processes.

Aluminum pipes are generally made by extrusion, which involves forcing aluminum billets through a die to create the desired shape. Pipes can also be made by drilling a hole through a solid aluminum billet. The resulting pipe is then welded together to create a seamless tube.

Both pipes and tubes can be cut to length, bent, and otherwise shaped to meet the needs of their intended applications. While aluminum pipes and tubes have many similarities, their different shapes and manufacturing processes give them distinct properties that make them better suited for different applications.

6. How to Work With Aluminum Tube Manufacturer

When it comes to working with aluminum pipe manufacturers, there are a few key steps that you need to follow to ensure a smooth and successful process.

Step#1 Establish Clear Expectations from The Beginning

It’s important to be clear about what you expect from your manufacturing partner right from the start. This means setting realistic deadlines, agreeing on quality standards, and discussing quantities well in advance. If any changes or surprises occur down the road, it will help to have already established a framework for communication so that everyone is on the same page.

Step#2 Follow up Regularly and Track Progress Closely

Checking in frequently is essential when working with any supplier, but it’s especially important when partnering with a manufacturer. By tracking production progress and sending samples for inspection along the way, you can avoid costly mistakes and ensure that your final product meets all of your expectations.

Step#3 Communicate Openly and Honestly

For any relationship to succeed, communication is key. This is especially true when working with an aluminum tube coil factory.

If there are any problems or concerns, be sure to address them immediately so that they can be resolved quickly and efficiently. By maintaining an open and honest dialogue, you’ll be able to build a strong partnership that will last for years to come.

Step#4 Be Flexible and Adaptable

The manufacturing process can be unpredictable, so it’s important to be flexible in your approach. If there are changes that need to be made, work with your manufacturer to find a solution that will work for both parties. By being adaptable, you’ll be able to overcome any challenges that come up and keep the production process on track.

Step#5 Have a Backup Plan

Despite your best efforts, there’s always a chance that something can go wrong during the manufacturing process. That’s why it’s important to have a backup plan in place so that you can keep your project on track even if there are delays or unforeseen problems.

By having a contingency plan, you’ll be able to minimize the impact of any issues and ensure that your project is completed on time and within budget.

So, don’t wait – start following these steps today and see how easy it is to work with an aluminum pipe factory. Contact us at Upaluminum to get started! We would be happy to help you with any questions that you may have.

7. Considerations When Choosing Manufacturer

When looking for an aluminum flat tube supplier, there are several factors you need to consider to find the best supplier for your needs. Here are a few things to keep in mind:

Location

You’ll want to choose a manufacturer that is located close to your business or customers. This will help reduce shipping costs and turnaround time. It’s also important to consider the location of the aluminum flat tube factory about the markets you serve.

However, some countries offer lower labor and materials costs. These can be a great option if you’re looking to save money on your aluminum tube order.

Capacity

It’s important to find a manufacturer that can meet your demand. You don’t want to be left without the products you need, so make sure they can keep up with your orders. Also, keep in mind that some manufacturers may have minimum order requirements, so be sure to check with them before placing your order.

Quality

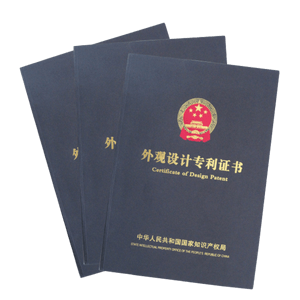

Of course, you’ll want to make sure you’re getting high-quality products from your manufacturer. Ask for samples and check out their previous work to get an idea of the quality you can expect. In addition, find out what kind of quality control measures they have in place to ensure that their products meet your standards.

Price

Get quotes from several manufacturers and compare prices to find the best deal. Be sure to factor in shipping costs and any other fees associated with the purchase. By considering all of these factors, you can be sure to find the best aluminum alloy tube factory for your needs.

Lead Time

Find out how long it will take for your products to be manufactured and shipped. You don’t want to be left waiting for your order when you could be selling to customers.

These are just a few of the things you need to keep in mind when choosing an aluminum alloy tube manufacturer. By taking the time to find the right supplier, you can ensure that you’re getting the best products for your business.

8. The Average Cost of Aluminum Tube

The average cost of an aluminum tube is $2.50 per foot. This price can change depending on the type of tube you are looking for, as well as the size and quality of the tube. However, this is the general price that most manufacturers will charge for this product.

If you are looking for a specific type of tube or a higher quality tube, then you may have to pay more than this general price. Special or custom-made types of aluminum tubes can cost more, averaging about $5 per foot.

9. 5 Buying Tips About Aluminum Tube

If you are planning to buy an aluminum tube, there are a few things that you need to keep in mind. Here are 5 tips that will help you buy the right product:

#1 Diameter

The diameter will determine the strength and weight of the tube. It is important to choose a tube with the right diameter so that it can support the load that you are planning to put on it. Aluminum tubes usually come in diameters of 1 to 8 inches.

#2 Thickness

Thicker tubes are usually stronger and can support more weight. However, they are also more expensive. Aluminum tubes typically come in thicknesses of 0.5 to 1 inch. Aluminum tubes thicker than these sizes are considered custom-made and will be more expensive.

#3 Length

The length of the tube will also affect the price. The longer the tube, the more expensive it will be. Aluminum tubes usually come in lengths of 4 to 8 feet. Custom-made aluminum tubes can be any length that you need them to be.

#4 Alloy Grade

The alloy is what gives the aluminum its strength. The most common alloys used in aluminum tubes are 6061 and 5052. These alloys are strong and can be used for a variety of applications.

#5 Finish

The finish of the tube will affect how it looks and how it performs. The most common finishes for aluminum tubes are anodized and powder-coated. Anodized tubes have a smooth, shiny finish that is corrosion-resistant. Powder-coated tubes have a matte finish that is also corrosion-resistant.

Want to know how aluminum tubes are made? This video is for you, take a look at this!

10. Conclusion

Aluminum tubes can be used in a variety of applications. They are widely used in construction and other industries. If you are planning to buy an aluminum tube, make sure to work with a reputable aluminum tube factory.

At Upaluminum, we have been in the business for years and have gained a reputation for providing high-quality products at competitive prices. Contact us today to learn more about our products and services. Get started with your bulk order today!