PRODUCT FEATURES

Aluminium Sheet Manufacturer to Rocket Your Business

PRODUCTS

Proud to Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today.

ABOUT US

Who is Upaluminum.com

Upaluminum.com have seen that today there are also many aluminum coils companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and upaluminum.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

BUYER’S GUIDE

The Ultimate Guide to Choosing Aluminium Sheet Supplier

If you’re in the market for aluminum coils, it’s important to choose a supplier you can trust. Not all suppliers are created equal, so it’s important to do your research before making a purchase.

In this article, we’ll provide an overview of what to look for when choosing an aluminium sheet supplier and share some tips for finding the best supplier for your needs.

So, if you’re ready to learn more about how to choose an aluminium sheet manufacturer, let’s get started!

Table of contents

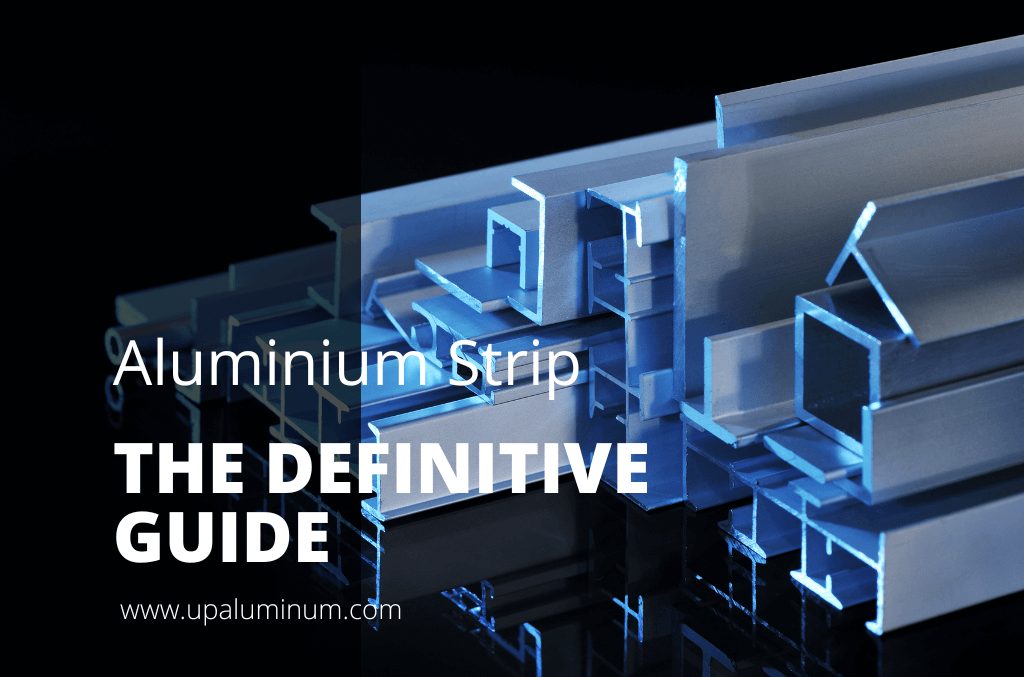

1. What Is Aluminium Sheet?

Aluminium sheet is a thin, flat piece of aluminium that is commonly used in construction and manufacturing. It is strong and durable, making it a popular choice for a variety of applications. aluminium sheet can be cut and formed easily, making it a versatile material for a variety of projects.

Aluminium sheet is available in a variety of thicknesses and grades. It is often used in construction, due to its durability and strength. Aluminium sheets can be cut and formed into a variety of shapes and sizes.

2. A Quick History Of the Aluminium Sheet Industry

Aluminium sheet has been around for over a hundred years. Through the years, the process of making these aluminium sheets have changed and improved a lot.

| 1908 | The first recorded use of aluminium sheets was in 1908. It was used by Henry Ford in his Model T cars. Aluminium was seen as a good choice for car bodies because it was strong yet lightweight. |

| 1923 | During the First World War, aluminium was used for aircraft construction. This led to an increase in demand and production of aluminium sheets. |

| 1938 | The first process for making aluminium sheets on an industrial scale was developed by Karl Jorgensen. This process is still used today. |

| 1940s-1950s | During the Second World War, aluminium was once again in high demand for aircraft construction. After the war, production continued to increase as aluminium became more popular for a variety of uses such as food packaging and roofing. |

| 1960s-1970s | The use of aluminium sheets continued to increase in the 1960s and 1970s. New processes and technologies were developed to meet the growing demand. |

| 1980s-Present | Today, aluminium sheet is used in a variety of industries and for a variety of applications. It is one of the most popular materials due to its many benefits. |

3. Features of Aluminium Sheet

Aluminium sheet is a versatile material that can be used for a variety of purposes. It has a variety of features that make it a good choice for a range of projects. Some of the key features include:

Lightweight

Aluminium sheet is a lightweight material, which makes it easy to work with and helps to reduce the overall weight of a project. This can be important for transportation or construction projects where weight is a key consideration.

Durable And Corrosion Resistant

Aluminium sheet is a durable material that is resistant to corrosion. This makes it an ideal choice for projects that will be exposed to the elements, such as cladding or roofing.

Fire Resistant

Aluminium sheet is fire resistant, which makes it an ideal choice for projects where fire safety is a concern.

Non-toxic

Aluminium sheet is a non-toxic material, which makes it a safe choice for projects where safety is a concern. Additionally, aluminium sheet is recyclable, which makes it a sustainable choice for projects.

Ductile

Ductile materials are easy to shape and mould into different forms. This makes aluminium sheets a great choice for businesses that need to create products with intricate designs.

These are just some of the key features of aluminium sheets. When choosing aluminum plate suppliers for your business, it is important to consider these factors to ensure you are getting a product that is right for you.

4. Advantages of Aluminium Sheet

When it comes to choosing an aluminium sheets supplier, you have a few options. But what are the advantages of aluminium sheets? Let’s take a look:

Low Maintenance

One of the main advantages of using aluminium sheets is that it is low maintenance. This means that it does not require a lot of upkeep and can be easily cleaned with a damp cloth. This makes it a great choice for businesses that are looking for a durable and easy-to-maintain material.

Resistant To Wear And Tear

Aluminium sheet is also resistant to wear and tear, meaning that it will not easily show signs of age or wear. This makes it an ideal choice for businesses that want a material that will last for many years.

Easy To Work With

Another advantage of aluminium sheet is that it is easy to work with. This means that it can be easily cut, bent, and shaped to suit your business’s needs. This makes it a great choice for businesses that are looking for a versatile material.

Environmentally Friendly

Finally, aluminium sheet is also environmentally friendly. This means that it can be recycled and used again, making it a great choice for businesses that are looking to reduce their carbon footprint.

As you can see, there are many advantages to using aluminium sheets. It’s up to you to decide which of these advantages is most important to your business. But, whichever way you choose, you can be sure that aluminium sheet is a great choice.

5. 9 Industrial Applications of Aluminium Sheet

Aluminium sheet is a versatile material that has many industrial applications. Some of the most common applications are listed below.

#1 Construction

Aluminium sheet is often used in construction, as it is durable and weather resistant. It is commonly used for cladding, roofing, and gutters.

#2 Automotive

Aluminium sheet is also used in the automotive industry, as it is lightweight and corrosion resistant. It is often used for body panels and engine components.

#3 Packaging

Aluminium sheet is often used in packaging, as it can be easily formed into different shapes. It is commonly used for cans, foil, and bottle caps.

#4 Electrical

Aluminium sheet is also used in the electrical industry, as it is a good conductor of electricity. It is often used for wiring and electrical components.

#5 Machinery

Aluminium sheet is often used in machinery, as it is strong and durable. It is commonly used for machine parts and components.

#6 Consumer Goods

Aluminium sheet is also used in the production of consumer goods, as it can be easily formed into different shapes. It is commonly used for kitchen utensils, appliances, and gadgets.

#7 Aircraft Manufacturing

Aluminium sheet is used in the manufacture of aircraft fuselages and other parts. It is strong and lightweight and can withstand the high temperatures associated with aircraft operation.

#8 Marine Applications

Aluminium sheet is used in a variety of marine applications, including boat hulls, boat decks, and boat fittings. It is strong and corrosion-resistant, making it ideal for use in wet environments.

#9 Signage

Aluminium sheet is commonly used in signage applications due to its durability and weather resistance. It can be easily etched or drilled to create custom signage designs.

These are just a few of the many industrial applications for aluminium sheet. As you can see, this versatile material can be used in a variety of industries and for a variety of purposes. If you need aluminium sheet for your business, be sure to contact a reputable aluminum sheet metal manufacturer such as Upaluminum who can provide you with the high-quality material you need.

6. The Manufacturing Process of Aluminium Sheet

The aluminum sheet is manufactured in a variety of ways, but here is the common step-by-step process:

Step #1 Gathering Raw Materials

Production begins with the processing of raw materials. The primary raw material for aluminum sheets is aluminum ingots. This is followed by the addition of a small amount of another metal, such as magnesium or silicon, which helps to improve the strength and durability of the finished product.

Step #2 Melting The Aluminum Ingots

Once the raw materials are gathered, they are placed in a furnace and heated until they melt. This process can take several hours.

Step #3 Casting The Aluminum

Once the aluminum is melted, it is poured into molds where it will cool and solidify. These molds come in a variety of shapes and sizes, depending on the desired final product.

Step #4 Rolling The Aluminum

After the aluminum has cooled and solidified, it is time to roll it into thin sheets. This is done by passing the aluminum through a series of rollers, each of which flattens it a bit more until the desired thickness is achieved.

Step #5 Cutting The Aluminum Sheets

The final step in the manufacturing process is to cut the aluminum sheets into the desired size and shape. This is usually done with a high-powered cutting machine.

Step #6 Quality Control

Once the aluminum sheet is cut to size, it is time for quality control. This is when the sheet is inspected for any defects or impurities. If any are found, they are removed and the sheet is then sent off to be used in its intended application.

This is the general process for how an aluminum sheet is manufactured. Of course, there are slight variations from one manufacturer to the next, but the overall process is generally the same. Knowing the steps involved in the process can help you to choose the right aluminum sheet metal supplier for your needs.

Here’s a video to learn more about the process of how aluminum sheet is manufactured, take a look at this!

7. How To Work With Aluminium Sheet Supplier

Now that you know a bit more about aluminum sheet and how it is manufactured, you may be wondering how to work with an aluminum sheet supplier. Here are a few tips:

Research The Supplier

It is important to research the aluminium sheet roll supplier before you make a purchase. You want to make sure that they are reputable and have a good track record.

Be Clear About Your Needs

When you contact the aluminium sheet metal supplier, be clear about your needs. You should have a list of specifications that you need the aluminum sheet to meet.

Ask Questions

Be sure to ask the supplier any questions that you have. You want to make sure that you understand everything about the product and the process.

Negotiate

Once you have found a supplier that you are happy with, it is time to negotiate. You should try to get the best price possible.

Sign A Contract

Once you have negotiated a price, it is time to sign a contract. This will protect both you and the painted aluminum sheet metal supplier.

These are just a few tips on how to work with an aluminum sheet supplier. By following these tips, you can be sure that you will be working with a reputable aluminium tread plate supplier that will provide you with the products that you need.

8. What to Look for in an Aluminum Sheet Supplier

When looking for an aluminum sheet supplier, it is important to consider the quality of the products offered, as well as the supplier’s ability to meet your needs. Here are some things to look for:

Quality Of Products

It is important to find a supplier that offers high-quality products. Look for a flat aluminum plate supplier that has a proven track record of delivering high-quality products.

Variety Of Products

A good supplier will offer a variety of aluminum sheet products, including different thicknesses and colors (e.g., black aluminum sheet, black anodized aluminum sheet, white aluminum sheet). This will allow you to find the right product for your needs.

Customer Service

It is important to find a supplier that provides great customer service. Look for a supplier that is willing to go the extra mile to help you find the right product and answer any questions you may have.

Expertise

The supplier’s expertise is another important factor to consider. Look for a supplier that has a lot of experience in the industry and can offer you advice on what products would be best for your needs.

Easy To Work With

Working with a supplier should be easy. Look for a supplier that is easy to communicate with and is willing to work with you to find the right product.

Looking for an aluminum sheet supplier that meets all of these criteria is not always easy, but it is worth the effort. By taking the time to find a supplier that meets your needs, you will be able to get the products you need at a price you can afford.

9. Cost Factors to Consider When Buying Aluminium Sheet

So, here’s the big question: how much does an aluminum sheet cost? There are a number of factors that will affect the price. Here is a look at some of the things that you need to consider when trying to determine the cost of an aluminum sheet.

Type Of Sheet

The first thing you need to consider is the type of sheet. There are 2 main types of aluminum sheets: rolled and extruded. The type of sheet you choose will affect the price.

Thickness

The thickness of the aluminum sheet is another important factor to consider. The thicker the sheet, the more expensive it will be. The reason for this is that thicker sheets are more difficult to work with and require more energy to produce.

Supplier

The supplier you choose will also affect the price. If you choose a local supplier, you will likely pay more for the aluminum sheet than if you choose an online supplier. The reason for this is that local suppliers have overhead costs that online suppliers do not.

Shipping

If you choose to have the aluminum sheet shipped to you, you will need to pay shipping costs. The cost of shipping will vary depending on the size and weight of the aluminum sheet.

Make sure to take all of these factors into consideration to get an accurate estimate of the cost of an aluminum sheet. Alternatively, you can always contact a local supplier for a quote.

10. 4 Buying Tips About Aluminium Sheet

When you are planning to buy an aluminum sheet, there are a few things that you need to consider to get the best deal. Here are some tips that you can use to make sure that you will be getting the best aluminum sheet for your business needs.

#1 Density

The first thing that you need to check is the density of the aluminum sheet. This will determine the strength and durability of the material. Make sure that you choose an aluminum sheet that has a high density so you can be sure that it will last long.

#2 Thermal Conductivity

Another thing that you need to consider is the thermal conductivity of the aluminum sheet. This will determine how well the material can dissipate heat. Choose an aluminum sheet that has a high thermal conductivity so you can be sure that it will not overheat.

#3 Strength

Strength is another factor that you need to consider when choosing an aluminum sheet. This will determine how well the material can withstand wear and tear. Choose an aluminum sheet that is strong enough to withstand the elements.

#4 Corrosion Resistance

Corrosion resistance is another factor to consider when choosing an aluminum sheet. This will determine how well the material can resist corrosion. Measuring the corrosion resistance of a material can be difficult, so it is important to consult with an expert before making a purchase.

It is important to keep these factors in mind when you are shopping for an aluminum sheet. By considering these factors, you can be sure that you will be getting the best deal on the market. With a little bit of research, you can find the perfect aluminum sheet for your business.

11. Conclusion

Aluminium sheet suppliers are many, making it difficult to choose the best one. However, with the guide above, you should be able to identify what you need and make an informed decision. Our team at Upaluminum is here to help with any questions or concerns that you may have during this process. We look forward to hearing from you soon!