PRODUCT FEATURES

Aluminium Strip Roll Manufacturer to Rocket Your Business

PRODUCTS

Proud to Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today.

ABOUT US

Who is Upaluminum.com

Upaluminum.com have seen that today there are also many aluminum coils companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and upaluminum.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

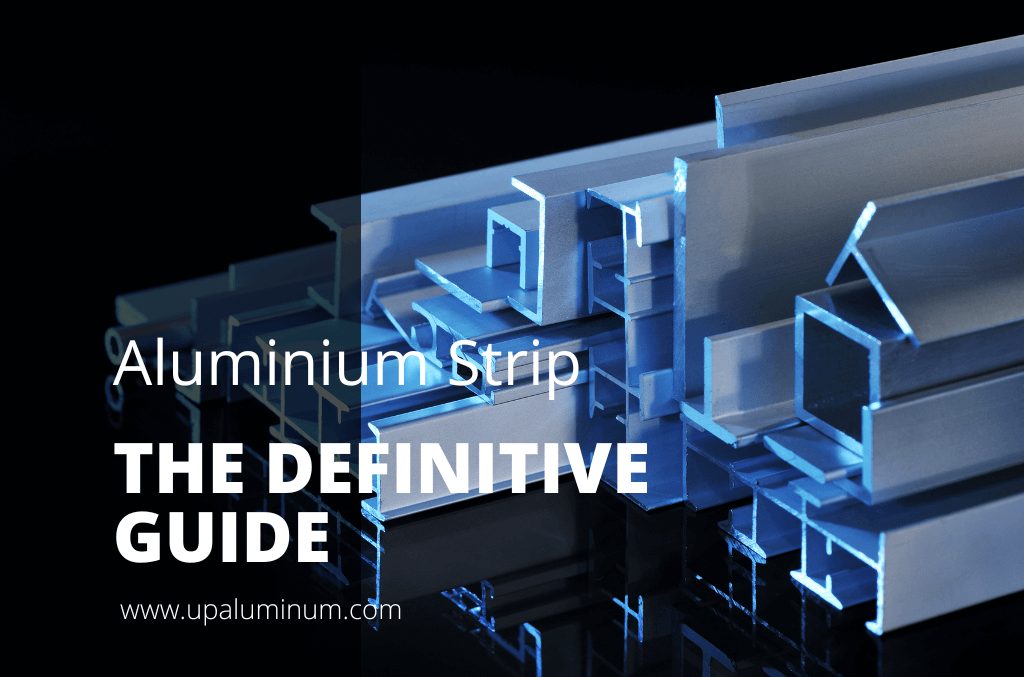

BUYER’S GUIDE

The Definitive Guide to Aluminium Strip Roll

If you are looking to buy aluminium strip rolls, then you need to understand the different types and how to choose the right one for your needs.

In this guide, we will discuss the different types of aluminium strip rolls, their applications, and how to select the right one for your business. We will also provide tips on buying these strip rolls and what factors to consider when making your purchase.

So, if you’re ready to learn more then let’s get started!

Table of contents

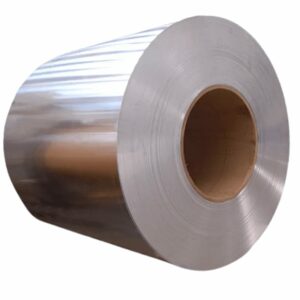

1. What is Aluminium Strip Roll?

Aluminium strip roll is a material made up of aluminium that has been formed into a thin sheet and then wound into a roll. This type of aluminium is used in a variety of industries, including the transportation and construction.

Aluminium strip roll can be cut to size and shape, making it an extremely versatile material. It is also resistant to corrosion and has a high strength-to-weight ratio, making it ideal for use in a variety of applications.

Interested to know about the aluminium rolling process? This video is perfect for you, check this out!

2. The Features of Aluminium Strip Roll

Aluminium strip roll is one of the most popular aluminium products on the market today. Thanks to its unique set of properties, it is used in a wide range of industries and applications. Here are some of the most notable features of this strip roll:

Lightweight

Aluminium strip roll is much lighter than other materials, such as steel. This makes it ideal for use in applications where weight is a concern, such as the transportation industry.

High Strength

Despite its lightweight nature, aluminium strip roll is actually very strong. It has a high strength-to-weight ratio, making it one of the best materials to use in applications where strength is a priority.

Corrosion Resistant

In most environments, aluminium forms a protective oxide layer that helps to prevent further corrosion. This oxide layer is also self-repairing, meaning that any damage caused by corrosion can quickly be repaired by the formation of the new oxide.

Aluminium’s resistance to corrosion means that it requires less maintenance than other materials, making it a more cost-effective option in the long run.

Non-Toxic

Aluminium is a non-toxic material, making it safe to use in a variety of applications. This makes it an ideal choice for use in food and beverage packaging, as well as in medical and dental implants.

Recyclable

Aluminium can be recycled indefinitely without losing any of its properties. This makes it an environmentally friendly option for use in a variety of applications.

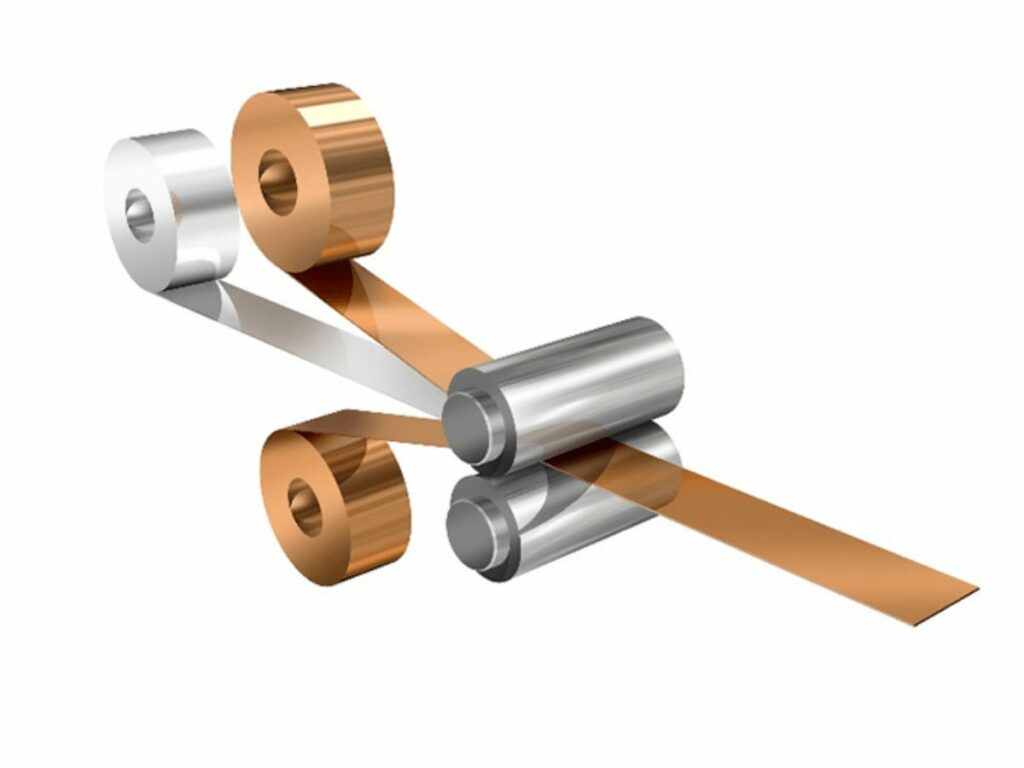

3. 5 Types of the Aluminium Strip Roll and Their Functions

Aluminium strip rolls are available in different widths, thicknesses, and alloys to cater to the specific needs of each industry. The most popular types of aluminium strip rolls are:

#1 Alloy Strip Rolls

Alloy strip rolls are made of an aluminum-copper alloy. Aluminum-copper alloys are made up of 90% aluminum and 10% copper. This means, alloy strip rolls offer high conductivity and good formability.

#2 Embossed Strip Rolls

Embossed strip rolls are made by passing aluminum sheets through a pair of rollers that have a design or pattern embossed on them. The process of embossing creates a raised or sunken design on the surface of the aluminum. Embossed strip rolls are often used in applications where a non-slip surface is required, such as stairs or ramps.

#3 Annealed Strip Rolls

Annealed strip rolls are made by heating aluminum sheets to high temperatures and then cooling them rapidly. This process makes the aluminum more ductile and less brittle. Annealed strip rolls are often used in applications where the aluminum needs to be formed into a specific shape.

#4 Clad Strip Rolls

Clad strip rolls are made by bonding a layer of aluminum to a layer of another metal, such as copper or steel. Clad strip rolls offer high strength and durability. They are often used in applications where the aluminum needs to be protected from corrosion or wear.

#5 Mirror Finish Strip Rolls

Mirror finish strip rolls are made by polishing the surface of the aluminum to create a reflective finish. Mirror finish strip rolls are often used in applications where a high level of reflectivity is required, such as in solar panels or mirrors.

4. The Aluminium Strip Roll Grades

The aluminium strip roll grades cover a wide range of specifications and properties. The most common grades are:

| Grade | Alloy | Features |

|---|---|---|

| CP-E | 99% aluminum and 1% iron | high purity and good formability |

| 3105 | 97% aluminum and 3% manganese | formability and corrosion resistance |

| 6061 | 97.5% aluminum, 1% magnesium, and 0.5% silicon | good weldability and strength |

| 7075 | 97.5% aluminum, 1% magnesium, and 2.5% zinc | high strength and durability |

CP-E

CP-E means commercial pure aluminium. This grade of aluminium strip roll is 99% aluminum and 1% iron. It is the most widely used grade of aluminium strip roll. This grade of aluminium offers high purity and good formability. It is often used in applications where the aluminum needs to be welded or brazed.

3105

3105 is made up of 97% aluminum and 3% manganese. This grade of aluminium offers good formability and corrosion resistance. It is often used in applications where the aluminum needs to be painted or anodized.

6061

The 6061 grade of aluminium is made up of 97.5% aluminum, 1% magnesium, and 0.5% silicon. This grade of aluminium offers good weldability and strength. It is often used in applications where aluminum needs to be formed into a specific shape.

7075

The 7075 grade of aluminium is made up of 97.5% aluminum, 1% magnesium, and 2.5% zinc. This grade of aluminium offers high strength and durability. It is often used in applications where the aluminum needs to be machined or forged.

5. Common Industry Application of Aluminium Strip Roll

There are a wide variety of industries that use aluminium strip rolls. Some of the most common industries include:

Aerospace

The aerospace industry uses aluminium strip rolls for a variety of applications. Aluminium strip rolls are often used to create fuel tanks, fuselages, and wing skins. They are also used to create other parts such as landing gear and brakes. They are also used in the construction of aircrafts, helicopters, and satellites.

Food Packaging

Aluminium provides an excellent barrier against moisture, oxygen, and other contaminants, making it ideal for food storage. Aluminium foil, for example, is often used to wrap around food items such as candy bars or baked goods. Aluminium containers are also used to store and transport pre-prepared foods such as chicken nuggets or french fries. Drink cans are also made from aluminium strip rolls.

Construction

Designers often prefer aluminium for construction applications because of its flexibility, durability, and low maintenance requirements. Aluminum can be formed into an infinite number of shapes and sizes, making it ideal for use in everything from window frames to cladding. Additionally, aluminium is lightweight yet strong, making it easy to transport and install.

Automotive

They are used in a variety of applications, from protective coatings to decorative trim. In recent years, aluminium strip rolls have become increasingly popular for use in hybrid and electric vehicles. They are also used in the manufacture of engine parts and components.

Electronics

Aluminium strip rolls are often used in the manufacture of electronic components and devices because they offer good conductivity and can be formed into a variety of shapes and sizes. They are often used in the production of printed circuit boards.

Medical

Aluminium strip rolls are extensively used in the medical industry because they are light in weight, have a low density, are non-magnetic, non-toxic, have good electrical and thermal conductivity, and are flame retardant. Aluminium strip rolls are used in the medical industry for making x-ray protection aprons, surgical instruments, IV poles, etc.

6. The Average Cost of Black Aluminium Strips

The price of black aluminum can range from $3 to $5 per square foot. Of course, the price will vary depending on the quality of the aluminum, the company you purchase it from, and the quantity you order.

If you’re looking for a more affordable option, you can try searching for recycled aluminum. It is a great option because it’s cheaper and it’s also more environmentally friendly.

7. Where Find Aluminium Strip Roll Manufacturers

There are a few ways that you can find aluminium strip roll manufacturers. Here are some places you can check out:

Google Search

One of the easiest ways to find manufacturers is to simply search for them on Google. You can use keywords such as “aluminium strip roll near me” or “aluminium strip coil suppliers”. This should give you a list of manufacturers in your area.

B2B Platforms

There are also many B2B platforms that you can use to find manufacturers, such as Alibaba and Global Sources. These platforms allow you to search for suppliers based on location, product, and other criteria. Using these websites should give you a good list of potential suppliers to contact.

Local Suppliers

This can be a great way to get high-quality products at a lower price, as local manufacturers will often have lower overheads and can pass on these savings to their customers. You can find local manufacturers by searching online directories or by asking for recommendations from friends or family.

Trade Shows

These events bring together suppliers and buyers from all over the world, so you will have a great opportunity to compare products and prices. You can also use trade shows to build relationships with potential suppliers, which can be beneficial if you plan on ordering large quantities of products in the future.

Manufacturer Websites

Many manufacturers have websites that you can visit. This is a great way to learn more about a company and its products. You can also usually find contact information on these websites, so you can get in touch with the manufacturer directly.

Upaluminum is one manufacturer you can trust. We are a professional aluminum manufacturer with years of experience and expertise. Contact us today to learn more about our products and services.

8. 6 Buying Tips About Aluminium Strip Roll

Now that you know a little more about aluminium strip rolls, here are some tips to help you when purchasing them:

#1 Thickness

Aluminum strip rolls come in different thicknesses. The most common options are between 0.5mm and 1mm. The thickness you need will depend on the application you’re using it for. If you’re not sure which thickness to choose, you can always ask the supplier for their recommendation.

#2 Width

These strips also come in different widths. The most common widths are between 10mm and 200mm. Again, the width you need will depend on the application.

#3 Length

The length of the strip will also vary. Some suppliers offer rolls that are only a few meters long, while others can be up to a hundred meters long. The length you need will depend on the project you’re working on. If you’re planning to sell it in retail, you might need a longer length so you can cut it into smaller pieces.

#4 Quality

When purchasing aluminium strips, you need to make sure you’re getting a high-quality product. The best way to do this is to buy from a reputable supplier. You can also ask for samples before making a purchase. This will allow you to see the quality of the product for yourself and make sure it’s up to your standards.

#5 Strength

The strength of the aluminium strip is also important. This will determine how well it holds up to wear and tear. You can actually test the strength of the strip by trying to bend it. If it bends easily, it’s not as strong as you need it to be.

#6 Finish

The finish on the aluminium strip is also something to consider. Some suppliers offer a matte finish, while others offer a glossy finish. The type of finish you choose will depend on the application

9. Conclusion

Aluminium strip roll is a flat, thin piece of metal that has been rolled into a coil. It is made from aluminum and has a variety of applications in different industries. if you’re looking for bulk quantities of this product, it’s important to find a reputable supplier.

One manufacturer you can check out is Upaluminum. We can help you find the right product for your needs and provide you with a quote. Contact us today to get started.