PRODUCT FEATURES

Aluminium Strip Manufacturer to Rocket Your Business

PRODUCTS

Proud to Offer a Wide Variety of Products

If you are looking for something specific that isn’t listed on our website yet, just contact us today.

ABOUT US

Who is Upaluminum.com

Upaluminum.com have seen that today there are also many aluminum coils companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and upaluminum.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Trusted by 530+ Top Companies

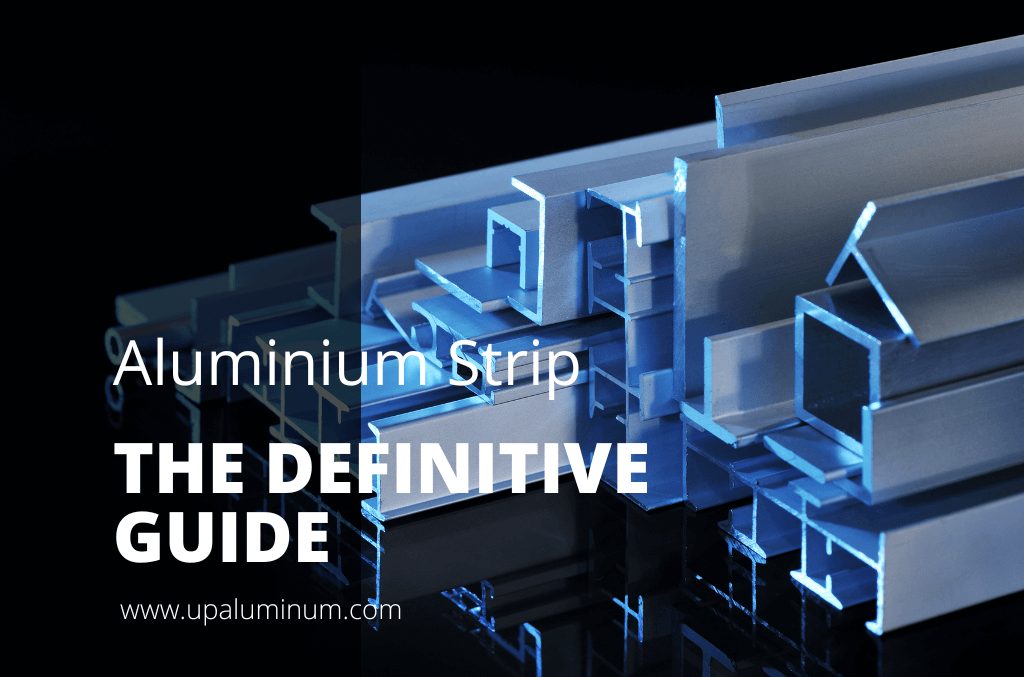

BUYER’S GUIDE

The Definitive Guide To Aluminium Strip

Aluminum is one of the most popular metals in use today. It has a vast number of applications and is used in many different industries. However, for all its popularity, aluminum can be quite confusing to those who aren’t familiar with it.

This guide is designed to provide you with all the information you need to make an informed purchase of aluminum strips. We’ll cover everything from types of aluminum strips to the various applications they’re used for.

So whether you’re a wholesaler looking to expand your inventory or a small business owner in need of a reliable source for aluminum strips, this guide is for you!

Table of contents

1. Overview: Aluminium Strip

Aluminium strip is an aluminium product that is characterized by its thinness and lightness. It is aluminium in its purest form, with a 99% aluminium composition.

Aluminium strip is made by passing aluminium sheet through a series of rollers to achieve the desired thickness. The strip is then annealed, or heat-treated, to soften it and make it more workable.

Aluminium Strip can be produced in a wide range of thicknesses, from 0.5mm to 10mm. Thinner strips are used for applications such as aluminium foil and aluminium tape, while thicker strips are used for construction and industrial applications.

Aluminium strip is a lightweight metal that has many desirable properties. It is corrosion-resistant, non-toxic, and has a high electrical conductivity. This makes flexible aluminium strips an ideal material for a wide range of applications.

2. What Aluminium Strip Is Used for?

Aluminium strips have a lot of uses that many people are not even aware of. It is a very versatile product with a wide range of applications in both industry and households. Here are some of the most common uses for aluminium strips:

Food and Beverage Packaging

Aluminium strips are often used in food and beverage packaging, such as cans, bottles, and wrappers. They provide a barrier against oxygen and other contaminants that can spoil food or cause health problems.

Insulation

White aluminium strips are also used in insulation applications. They help to keep homes and buildings warm in winter and cool in summer, by reflecting heat away from the interior.

Air Conditioning

Aluminium strips are used in air conditioning systems to improve their efficiency. The aluminium reflects heat away from the coils, which helps to keep the coolant inside at a lower temperature.

Electrical Applications

Aluminium strips are also used in a variety of electrical applications, such as wiring and cables. They are an excellent conductor of electricity and have a high resistance to corrosion.

Building Construction

Aluminium strips are often used in building construction, for both structural and aesthetic purposes. They are used in window frames, doors, cladding, and roofing. This metal is also used to create gutters, downpipes, and rainwater tanks.

These are just some of the most common uses for aluminium strips. This versatile product has a wide range of applications, making it an essential part of many industries.

3. 3 Types of Aluminium Strip and Their Functions

There are many types of aluminium strips, each with its own unique set of properties and functions. Here is a brief overview of some of the most common aluminium strips:

#1 Annealed Aluminium Strip

Annealed aluminium strip is the most common type of aluminium strip. It is soft and malleable, making it ideal for applications that require frequent bending or shaping. Annealed aluminium strip is also easy to weld and cut, making it a versatile choice for many applications.

#2 Cold-Rolled Aluminium Strip

Cold-rolled aluminium strip is much harder and less malleable than an annealed aluminium strip. It is often used in applications where a high degree of precision is required, such as in the automotive industry.

#3 Hot-Rolled Aluminium Strip

Hot-rolled aluminium strip is aluminium that has been rolled at a high temperature, typically above 700 degrees Fahrenheit. This gives the aluminium strip a softer, more malleable texture that can be easily worked into new shapes. Hot-rolling is also used to increase the aluminium’s strength and hardness.

These are just a few of the most common types of decorative aluminium strips. Each type of aluminium strip has its own unique set of properties and advantages, making it suitable for different applications.

Looking for aluminium strips for your next project? Visit our website at Upaluminum to browse our selection of aluminium strips and find the perfect one for your needs. We offer a wide variety of aluminium strips, in a variety of sizes, thicknesses, and grades. We’re sure to have the perfect aluminium strip for your application. Contact us today to learn more.

4. Different Grades of Aluminium and Their Uses

Aluminium is a versatile metal that can be used for a variety of applications. It is available in a variety of grades, each with its own unique set of properties and characteristics. Here are the most common grades of aluminium:

| Grade | Alloy | Features |

|---|---|---|

| 1000 Series | 99% pure aluminum | Electrically conductive |

| 2000 Series | Copper | Increased Strength |

| 3000 Series | Manganese | Food safe |

| 4000 Series | Silicon | Lower Melting Point |

| 5000 Series | Magnesium | Higher commission resistance |

| 6000 Series | Magnesium and Silicon | Respond well to heat treatment |

| 7000 Series | Zinc | High Strength |

1000 Series

This is the purest aluminium grade, with a minimum of 99% aluminium content. It is soft and ductile, making it ideal for applications that require high levels of malleability.

2000 Series

This aluminium grade is alloyed with copper, giving it increased strength and hardness. It is often used in applications that require high levels of strength, such as armour plates.

3000 Series

This aluminium grade is alloyed with manganese, giving it enhanced strength and durability. It is often used in construction applications, such as roofing and siding.

4000 Series

This aluminium grade is alloyed with silicon, giving it increased strength and stiffness. It is often used in applications that require high levels of durability, such as automotive parts.

5000 Series

This aluminium grade is alloyed with magnesium, giving it enhanced strength and corrosion resistance. It is often used in marine and aerospace applications.

6000 Series

This aluminium grade is alloyed with magnesium and silicon, giving it increased strength and corrosion resistance. It is often used in marine and aerospace applications.

7000 Series

This aluminium grade is alloyed with zinc, giving it enhanced strength and hardness. It is often used in armor plates and other applications that require high levels of strength.

These are just a few of the most common aluminium grades. Each has its own unique set of properties and characteristics, making it ideal for specific applications. When choosing an aluminium grade, it is important to consider the intended use of the material to ensure that the right grade is selected.

5. How To Cut and Bend Aluminium Strip

Aluminium strip can be cut and bent to create a variety of shapes and sizes. Here are the steps on how to do so:

Step#1 Mark Where You Need to Cut

Use a sharpie or other marker to mark where you need to cut the aluminium strip. Make sure that the line is straight and even.

Step#2 Cut Along the Marked Line

Using a sharp knife or aluminium shears, cut along the marked line. If you’re using aluminium shears, you may need to apply some pressure to get through the thicker parts of the strip to make a clean cut.

Step#3 Bend the Aluminium Strip

Next, it’s time to bend the aluminium strip. You’ll need a mallet or hammer for this step. Place the aluminium strip on a work surface and gently tap it until it reaches the desired shape. If you’re working with a small piece of aluminium, you may be able to bend it by hand. Just be careful not to overdo it or you may break the strip.

Step#4 Add Finishing Touches

Once you’ve cut and bent the right angle aluminium strip to your liking, it’s time to add any finishing touches. You can use a file or sandpaper to smooth out any sharp edges. If you want to give the aluminium a polished look, you can use a metal polish. Just apply it to the aluminium strip with a clean cloth and buff it until it’s shiny.

Now that you know how to cut and bend aluminium strips, you can use them for a variety of projects. Just be sure to choose the right type of aluminium for your project and follow the steps above carefully to ensure safe and successful results.

6. Common Industry Applications of Aluminium Strip

Aluminium strips are widely used in various industries due to their unique properties. Some of the most common industry applications are:

Automotive Industry

The automotive industry is the largest consumer of aluminium strips. Aluminium strips are used in cars for various purposes such as body panels, doors, windows, etc.

Construction Industry

Aluminium strips are widely used in the construction industry due to their high strength-to-weight ratio. They are used in the construction of buildings, bridges, and other structures.

Electrical Industry

Aluminium strips are widely used in the electrical industry due to their excellent electrical conductivity. They are used in the manufacture of electrical cables and wires.

Consumer Goods Industry

Aluminium strips are widely used in the consumer goods industry due to their low cost and good mechanical properties. They are used in the manufacture of various consumer products such as appliances, furniture, etc.

These are just some of the many common industry applications of aluminium strips. Bendable aluminium strips are truly versatile and have a wide range of applications to suit various industries.

7. Average Cost of Aluminium Strip

Aluminium strip is a popular choice for a variety of applications, from construction to automotive. The average cost of aluminium strip will vary depending on the type of aluminium and the thickness required. Generally, the cost of aluminium strip can range from $2-$5 per kilogram.

This cost can fluctuate depending on the market and aluminium strip prices at the time of purchase. For thinner aluminium strips, the price may be on the lower end, while thicker aluminium strip can cost more.

When choosing aluminium strip for a project, it is important to consider the cost as well as the quality of the aluminium. Choosing a cheaper aluminium may mean sacrificing quality, which could lead to problems down the road. It is important to balance cost with quality to ensure that the aluminium strip will meet the needs of the project.

8. 5 Buying Tips About Aluminium Strip

If you’re in the market for aluminium strip, there are a few things you should keep in mind to ensure you’re getting the best possible product for your needs. Here are a few tips to help you buy aluminium strip:

#1 Material

The first thing you need to consider when purchasing aluminium strips is the material. There are two main types of aluminium strips on the market: pure aluminium and aluminium alloy. Make sure to choose a material that is appropriate for your needs. Otherwise, you may end up with a strip that is too soft or too brittle.

#2 Thickness

The next thing to consider is the thickness of the aluminium strip. This will determine how strong and durable the strip is. There are a variety of thicknesses available on the market, from 1mm thick to 6mm aluminium strips. Choose the thickness that best suits your needs.

#3 Width

When purchasing aluminium strips, you will also need to consider the width. The width of the strip will determine how much aluminium you can use at one time. There are a variety of widths available on the market, from 50mm x 2mm to 1000mm x 10mm.

#4 Grade

The grade of aluminium is another important factor to consider when purchasing aluminium strips. The grade indicates the purity of the aluminium and its strength. There are a variety of grades available on the market, from 1000 to 7000 series. Choose the grade that can best meet your needs.

#5 Surface Finish

Finally, you need to consider the surface finish of the aluminium strip. The surface finish will determine how smooth and shiny the final product is. There are a variety of surface finishes available on the market, from anodized to polished.

These are just a few things to keep in mind when purchasing powder coated aluminium strips. By following these tips, you can be sure to find the best possible product for your needs.

If you’re looking for aluminium strips, be sure to check out our website at Upaluminum. We are aluminum strip suppliers that offer a wide range of aluminium strips for sale. We can also custom-cut aluminum strips to your desired length and width. Contact us today to learn more.

9. Conclusion

So there you have it, the definitive guide to aluminium strip. We hope you found this post helpful and that it has answered any questions you may have had about this versatile material.

If you have any questions or would like to discuss your specific needs in further detail, please don’t hesitate to contact us at Upaluminum. We would be happy to discuss your specific needs and see how we can help.